Better Performance Starts with Better Maintenance

Our expert cleaning, repair, and testing services restore airflow, improve fuel efficiency, and extend the life of your emission system.

-

Soot and ash build up within your DPF will restrict exhaust flow and disrupt the smooth running of your engine. This will cause excessive fuel use , low power, early engine and associated exhaust stream component wear, and unplanned maintenance and repairs.

Because a DPF is primarily a “Wall Flow” Filter the ash is trapped within the DPF and must be removed periodically.

Cleaning intervals depend on the type of use the vehicle is exposed to. Highway running vehicles need less of a interval (1yr) then school bus or garbage pick up vehicles, these have a far more demanding duty cycle.

A clean DPF ensures optimum engine power, performance and fuel economy, reducing the risk of unplanned maintenance expenses and down time. This will help your bottom line $

-

Initial inspection and flow restriction recorded.

Pneumatic blow out from top and bottom

Thermal baking under programmed temperature ramp control

Post Thermal Pin point pneumatic cleaning of cells from top and bottom

Multiple position flow testing

Final inspection and report

Our Services

-

DPF, DOC & SCR Cleaning

Thorough, professional cleaning that restores airflow, improves fuel efficiency, and extends the life of your equipment.

-

Aftermarket DPF & DOC Sales

High-quality aftermarket parts for all major truck and equipment brands. Reliable, durable, and ready when you need them.

-

Repairs & Replacements

Bung & flange repairs

Clamps & gasket replacements

Housing assessments

Flow restriction testing

+ And More

The Process

Step 1

Maximum Cleaning Efficiency

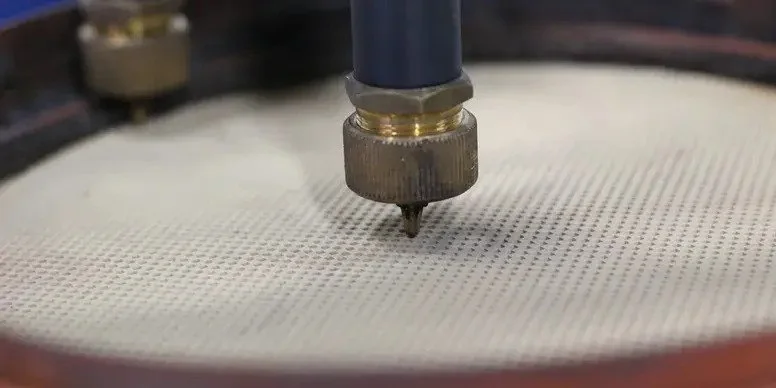

Pin point needle jets allow air to every cell, ensuring maximum cleaning efficiency

Step 2

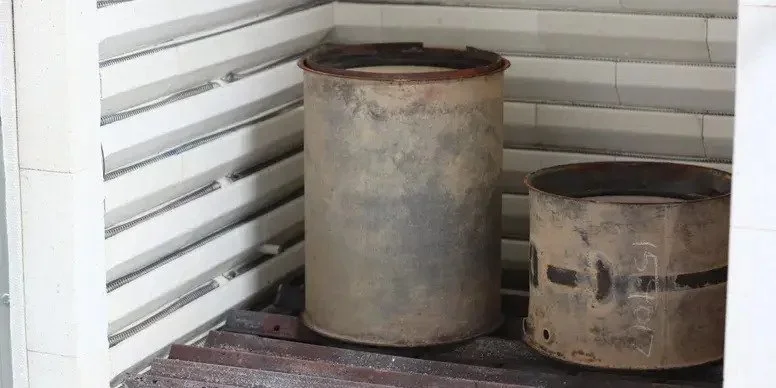

Large Kiln for Multiple DPF'S & DOC'S

Controlled thermal cycle with temperature ramping control to ensure maximum soot oxidation to ash.

Step 3

Flow Restriction Testing

Advanced flow restriction testing, allowing multiple test sites all around the DPF

Step 4

Thermocouple and Backpressure Port Replacement

Thermocouple and Backpressure Port Replacement

We will replace damaged T/C and BP couplings, as well as outer structure and flange replacement or repairs.

We will replace damaged T/C and BP couplings, as well as outer structure and flange replacement or repairs.

Frequently Asked Questions

-

Soot and ash build up within your DPF will restrict exhaust flow and disrupt the smooth running of your engine. This will cause excessive fuel use , low power, early engine and associated exhaust stream component wear, and unplanned maintenance and repairs.

Because a DPF is primarily a “Wall Flow” Filter the ash is trapped within the DPF and must be removed periodically.

Cleaning intervals depend on the type of use the vehicle is exposed to. Highway running vehicles need less of a interval (1yr) then school bus or garbage pick up vehicles, these have a far more demanding duty cycle.

A clean DPF ensures optimum engine power, performance and fuel economy, reducing the risk of unplanned maintenance expenses and down time. This will help your bottom line.

-

Initial inspection and flow restriction recorded.

Pneumatic blow out from top and bottom

Thermal baking under programmed temperature ramp control

Post Thermal Pin point pneumatic cleaning of cells from top and bottom

Multiple position flow testing

Final inspection and report

-

We’re a family-owned business that believes in doing things the right way. That means honest recommendations, high-quality workmanship, and treating every customer like family. We focus on fast turnaround times, reliable results, and long-term relationships; not quick fixes. When you work with us, you get experienced service, clear communication, and solutions you can trust.

-

GESI Global Emissions Systems Inc.

We use high-quality aftermarket DPF and DOC products built to OEM standards. All components are designed for exact-fit OEM replacement, allowing for fast, straightforward installation without modifications.

Our products are:

Built to OEM standards

Exact-fit replacements for easy installation

Manufactured in North America

Made using North American parts

Tested for durability and performance

-

Pricing varies depending on the vehicle, service, and parts required.

You can contact us here.

-

You can contact us here.